Polub nas na Fecebook'u!

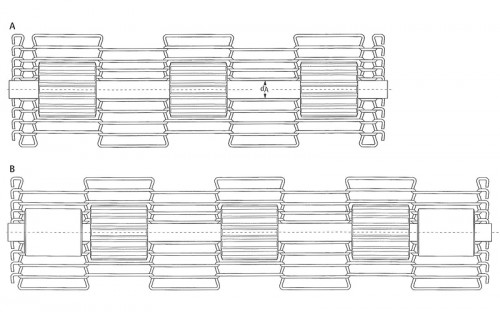

Rod network bells are driven by shafts with mounted drive sprockets. The layout of the drive sprockets is shown in the sketches.

Version "A": Rod network belt with gear wheel edge.

Version "B": Rod network belt without gear wheel edge.

We simply ready-assembled shafts or individual drive sprockets for self-assembly.

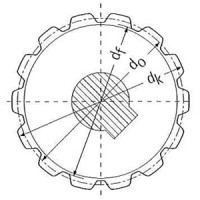

Guide value for drive sprocket widths

Mesh length -10 mm.

There are no standard dimensions

The drive sprockets are produced according to customer requirements.

Material

Shafts = Steel, stainless steel

Drive sprockets = Polyamide, steel, stainless steel

Assembly instruction

A ring mark is turned into the drive sprockets on one side. When assembling the drive sprockets, attention must be paid that all marks point in the same direction.

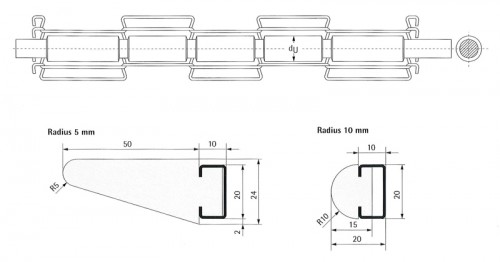

Plastic nose bars

As an alternative to a shaft made of steel or stainless steel, we also supply plastic nose bars.

Recesses are not required.

The plastic nose bars reduce belt wear to a minimum.

Material:

Section

Low-pressure polyethylene, while, Foodstuff-proof

Fastening rails

Steel, galvanized or stainless steel. Standard delivery length 2.000 mm.